Introduction Tire cutting equipment is an essential tool for anyone involved in the recycling industry. It allows us to transform old, worn-out tires into valuable resources that can be reused in a variety of applications. With tire recycle cutter, we can cut all kinds of tires, from steel tires to fiber tires, and turn them into manageable blocks that can be efficiently processed.

Not only does this process help to reduce the amount of waste in our landfills, but it also contributes to the conservation of our natural resources. By reusing old tires, we can reduce the need for new tires to be manufactured, which in turn conserves energy and reduces carbon emissions.

Furthermore, tire cutter plays a critical role in creating job opportunities in the recycling industry. As more and more people recognize the value of recycling, the demand for tire cutting equipment and other recycling technologies continues to increase. This creates jobs for individuals who are passionate about protecting the environment and shaping a more sustainable future.

Structure and principle The blades of Car Tire Cutter are made of high quality imported materials, wear-proof, heavy-duty and long life.

The rolling shelf and rotary platform make the operation easy and quick.

Automatic reposition function after each cut. With blocking pole to avoid tires sticking.

The hydraulic system of Tire Cutter adopts international advanced constant power variable plunger pump technology, low noise, and high pressure and improved the stability and life of the machine.

Technical Data

Model

| ZQJ-1200

|

Capacity

| 40~80 pcs/hr

|

Type of tires

| ≤1200mm diameter

|

Motor Power

| 5.5Kw

|

Working pressure

| 12Mpa

|

Weight

| 2500kg |

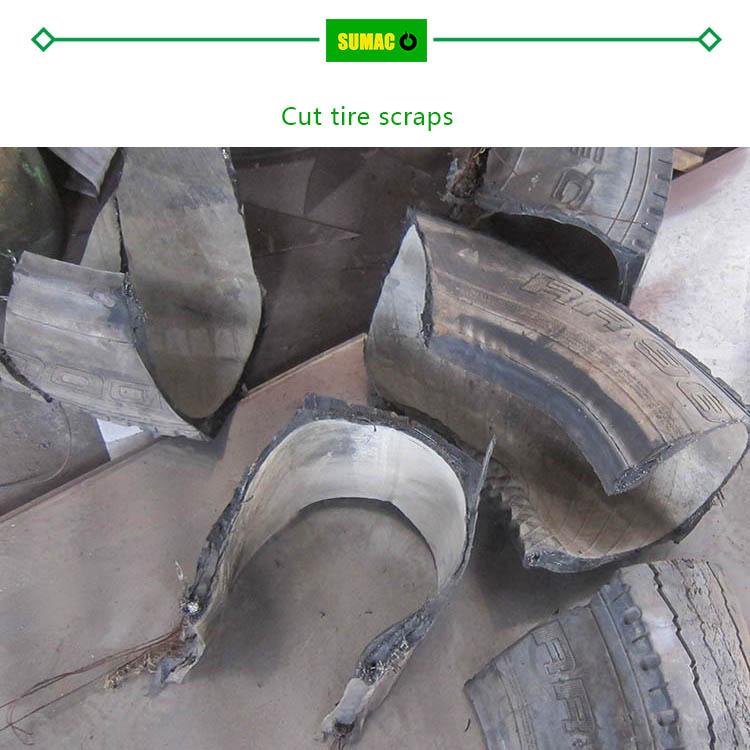

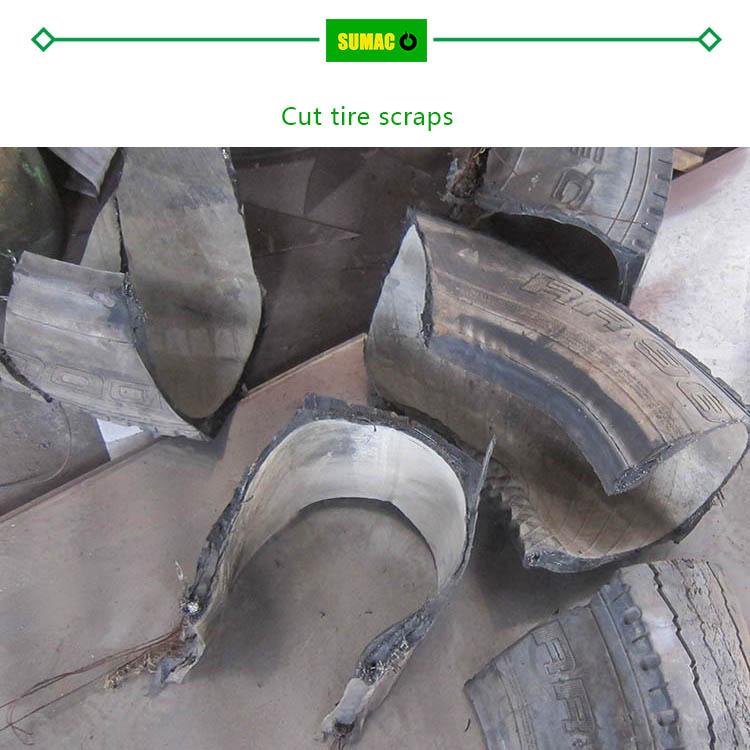

Final product

Advantages