1. Introduction

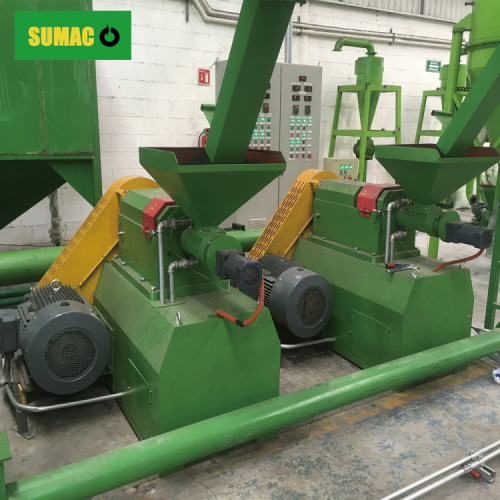

1). The Rubber Grinder Machine is used to grind 1-6mm rubber granules into 30-100 mesh rubber u

nder normal temperature.

2).

Rubber Fine Powder Grinder Consists of motor, drive plate, milling motor, feeding motor, mill discs, frequency conversion feeder and water-cooling system.

3). Capacity will be determined as the final rubber powders’ fineness.

4). Cooling system: Water-Cooling.

5). Also be used in Tire Recycling Line.

2. Structure and Principle

1). The Rubber Mill uses tungsten carbide as the milling surface of the milling disc;

The milling disc base is made of special treated materials, crashing-proof, wearable, durable and good ductility.

2). The Rubber Powder Mill adopts horizontal structure.

Most parts are CNC processed to ensure the installation accuracy.

Compact structure, low power and vibration, easy operation and maintenance.

3). Servo motor and inverter control system instead of chain and chain wheel.

It makes the whole machine reach the digital control, the feeding speed very stable and the output size same.

4). Internal circulating water cooling system can ensure ideal temperature for the milling discs during production.

The rubber powder will not get burned or sticky.

3. Technical data

Model

| CXFJ-28 rubber mill

|

Power

| 30.2 kw

|

Size of input

| 1-4 mm

|

Size of output

| 30-100mesh

|

Capacity

| 40-150 kg/h

|

Grinding Temp

| =<30 °C

|

Weight

| 1200 kg

|

Dimension

| 1920x1250x1320 mm

|

4. Millstone

5. Packing & Delivery