Recycling car tyre bead wire remover machine

Get Latest Price| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Recycling car tyre bead wire remover machine |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Recycling car tyre bead wire remover machine |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

Model No.: SL-1200

Brand: SUMAC

Place Of Origin: China

Types Of: Tire Machine

Old And New: New

Video Factory Inspection: Provided

Mechanical Test Report: Not Available

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Motor

Tyre Machinery Type: Tire Recycling Machine

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Out-of-warranty Service: Video Technical Support, Online Support

Applicable Industry: Other

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Name: Recycling car tyre bead wire remover machine

Capacity: 60~100 pcs/hour

Outer Diameter Of The Tire: ≤ 1200 mm

Pulling Force: 30 T

System: Circuit protection system

Dimension: 2250x1660x1500mm

Machine Type: Double hooks

End Product: No tire bead wire

Weight: 6500kg

| Selling Units | : | Set/Sets |

| Package Type | : | Plastic sketch film on the machine, with wodden box package or load into a 20GP container |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Tire Wire Remover Machine is an incredible innovation that helps in recycling waste tires and creating a greener environment. With this efficient machine, steel wires can be easily removed from waste tires, which can then be reused in numerous industries. It is a boon for tire recycling plants that deal with a large amount of waste tires daily.

Tire debeader is designed to remove steel wires from tires quickly and efficiently. It has a high efficiency rate that ensures the tires are processed in a timely manner. It is easy to operate, making it suitable for use by operators without any particular expertise or prior experience.

Tire steel wire remover provides an excellent solution for recycling waste tires, which is essential in protecting the environment. By recycling waste tires, we can reduce the pressure placed on landfills and help to reduce environmental pollution caused by the indiscriminate disposal of tires.

Structure & principle

The tire debeader is an innovative piece of equipment that has been designed to significantly enhance the process of recycling tires. This machine is an advanced cutting-edge technology equipped with several features that make it highly efficient, reliable, and safe to use.

One of the key features of this machine is the motor and twin hooks, which allow it to pull out bead wires at three times the speed of a single hook debeader. This makes the process quicker, reducing the time it takes to recycle tires.

The mechanical transmission and round hook design also make the tire debeader highly efficient, with a small occupation area. This means that it can be used in a variety of settings, including industrial and commercial environments.

Safety is also a top priority when it comes to the design of the tire debeader. It comes with a circuit protection system and a safety protection frame to make operation easy and safe. This ensures that workers are not placed at risk when using the machine.

The round hook, cross hole plate, and gears are made of materials that have undergone special treatment to make them durable, heavy-duty, and easy to maintain. This helps to extend the life of the machine, reducing the need for frequent repairs and replacements.

Technical Data

| Model | SL-1200 Tire Debeader |

| Capacity | 60~120pcs/hour |

| Type of tires | ≤1200mm |

| Powder | 15KW |

| Pulling force | 30T |

| Weight | 6500kg |

| Dimension | Dimension |

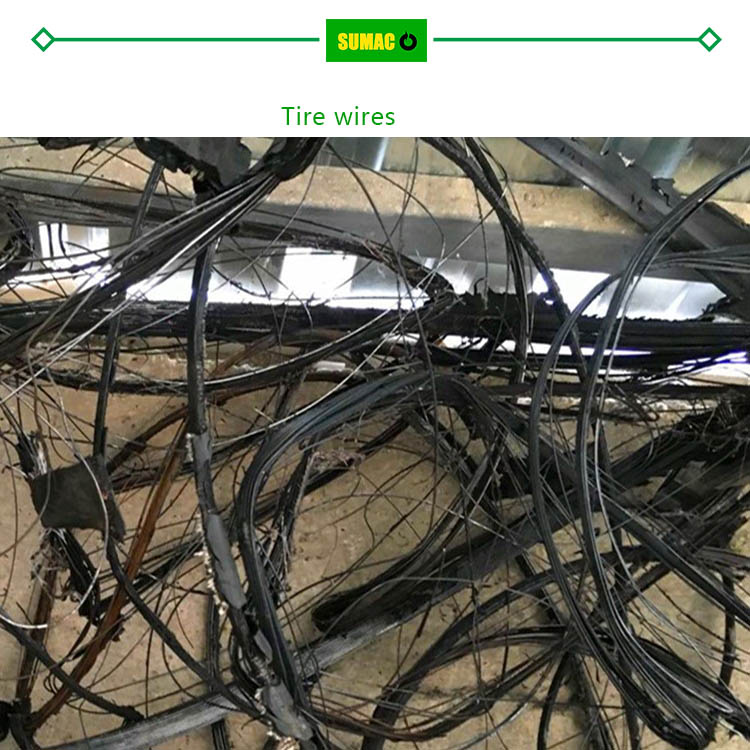

Output

Packing & Delivery

Company Information

Sumac was established in 2011, specialized in tire rubber recycling and metal recycling industries. In 2015, SUMAC cooperated with ARS (Australia) to design and manufacture ELV recycling and dismantling equipments. We are committed to solving global recycling problem of end-of –life vehicles and will become the world leader in ELV recycling industries.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.